When the robot arm says NO, you probably have OT network problems.

It is difficult to operate an IIoT environment without a proper OT network, as it is the backbone of its operation. The foundation of Industry 4.0 is reliable M2M and IoT communication.

For countless reasons, the control of a smart factory communicates with equipment, robots, environmental sensors throughout the facility, and sometimes even outside it. There are many aspects to consider when building an industrial network. Now we present a low-cost, fast-deploying solution for wireless implementations.

WHAT IS THE BLOG ABOUT?

- DAP ACCESS POINTS

- INDUSTRY 4.0 EXPECTATIONS

- HOW DAP WIFI MESH WORKS

OT network in WiFi MESH?

Yes! OT WiFi MESH with native industrial communication, remote management, cyber protection, various VPN options, in a real industrial environment. But this is not a question when it comes to a Teltonika solution, since these are all considered fundamental for the Lithuanian manufacturer. The question is more how or why. In the blog, we will briefly answer both questions. The starting point of the solution is Teltonika’s DAP industrial access points introduced last year.

What is DAP?

The DAP140, DAP142 and DAP 145 are industrial IoT/M2M Wi-Fi access points designed to meet the needs of industrial wireless networks and IIoT solutions. The DAP series wireless access points perform a similar function as any other WiFi access point, but their accompanying features, endpoint usage and last but not least their overall architecture are quite different.

Let’s start with the basic specifications. Both the DAP140 and DAP142/DAP145 are equipped with Wi-Fi 4 capabilities, passive PoE-in and two 10/100 RJ45 connectors. The DAP142 also provides with 1 port of RS232, and the DAP145 with 1 port of RS485. Each can support up to 50 simultaneous industrial connections.

As you would expect from Teltonika’s networking products, DAP devices are packed with security features, including multiple authentication and access control methods, firewall and intrusion prevention, and supported VPN protocols such as OpenVPN, ZeroTier, BacNET, and WireGuard.

What makes these wireless access points industrial?

First of all, their design makes it. Unlike office APs, which blend in with commercial and corporate environments with their elegant plastic casing, these DAP access points come in a rugged aluminum housing. This design allows them to withstand the most challenging industrial environments, including temperatures ranging from -40°C to +75°C.

Second, the DAPs feature industrial WiFi MESH and Fast Roaming capabilities. The WiFi MESH capability of the access points is particularly significant; a well-distributed fleet of these access points can create a wider coverage area in industrial, small data packet environments, and does not require any special cabling.

Finally, if we also use the wired connections of the APs, since end-point devices and industrial equipment can be directly connected via RJ-45/RS232/RS485 ports, it shows a reverse approach to classic enterprise WiFi AP solutions.

WiFi MESH for industrial applications

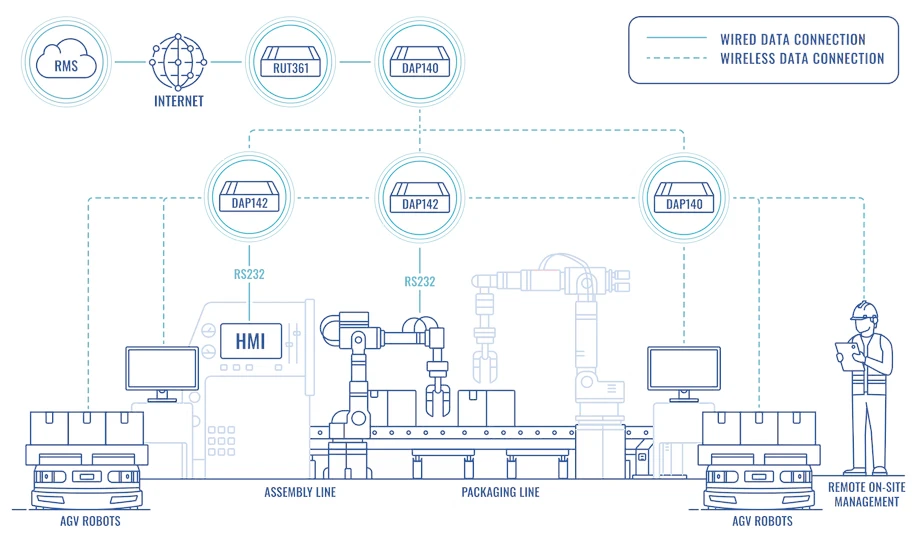

To better understand the value of these devices in industry, we show a smart factory configuration running on a DAP WiFi network full of classic IIoT equipment: assembly and packaging lines, AGV robots, HMIs, control PCs.

To take advantage of automation, these require connectivity and network centralization. Using an industrial WiFi MESH network built with DAP access points designed specifically for industrial applications is significantly less expensive than building a wired network and, last but not least, more efficient in this environment.

Why is a reliable network connection important?

A smart, Industry 4.0-based factory uses a variety of automation technologies to eliminate human errors, maximize efficiency and productivity, minimize costs, and extract and process detailed operational data, which is the starting point for future developments.

In such smart factories, the integration and connectivity of machines into the network is a vital issue. A reliable network is the moving spring of this innovative system, without which the equipment cannot communicate with each other. Thus, connectivity and network centralization are top priorities for industrial automation as well. In the context of factories – industrial spaces of several thousand square meters – every square centimeter of the facility and the machines inside it must be connected. DAP WiFi MESH systems are the perfect alternative for this: they are designed for industrial communication and environment.

THE SOLUTION

The basis of this industrial IoT solution can be, for example, the Teltonika RUT361 mobile /WAN failover router, which supplements the factory network with an LTE Cat 6 connection. The router can reach mobile speeds of nearly 300 Mbps even in the event of a wired internet outage. Of course, a dual-modem 5G device with a larger knowledge base can also be used, but the RUT361 has proven to provide satisfactory performance in an IoT/M2M industrial environment.

The RUT361 router is connected to a Teltonika DAP140 access point by wire via its RJ45 connector. From there, this access point communicates wirelessly with a fleet of additional access points located in the facility, which consists of various DAP140, DAP142, and DAP145 devices. The access points communicate both wirelessly and via a serial port connection with the endpoint units, resulting in a robust network. This is due to the fact that each WiFi access point supports 50 industrial connections at the same time mainly transmitted small data packets.

For the most critical locations and solutions, there is a setting that allows the RUT361 to automatically switch between cellular and wired Internet access. This simple automation eliminates unplanned downtime and data retrieval delays caused by offline status. Guaranteed continuous access can be reinforced by using industrial antennas that improve signal transmission, as both the router and access points can be installed with additional antennas.

Summary

DAP access points enable a cost-effective and simple WiFi MESH network. This network maximizes the potential of wireless connectivity in industrial environments, covering all equipment in the smart factory, thus enabling full-scale automation. With DAP-based industrial network centralization, the level of automation can reach and even exceed Industry 4.0 standards.

Related products

The Teltonika DAP140 is an industrial wireless access point with passive PoE input, designed to improve Wi-Fi coverage and performance – in industrial environments.

The Teltonika DAP142 is an industrial wireless access point with RS232 port and passive PoE input, designed to improve Wi-Fi coverage and performance in industrial environments.

The Teltonika DAP145 is an industrial wireless access point with RS485 port and passive PoE input, designed to improve Wi-Fi coverage and performance in industrial environments.

Our engineers can provide further information. If you have any questions, please do not hesitate to contact us!